IBAG High Speed Spindles

At IBAG, we believe that experience is vital to the success of any project. That is why we rely on our 75 years of industry knowledge to deliver high speed CNC machine spindle assemblies that are designed to your specification requirements.

If you have specific questions regarding our CNC high speed spindle options, get in touch with our sales team or call us at 203-407-0397 and we will gladly speak to you regarding your project’s specifications.

High Frequency Spindle Systems

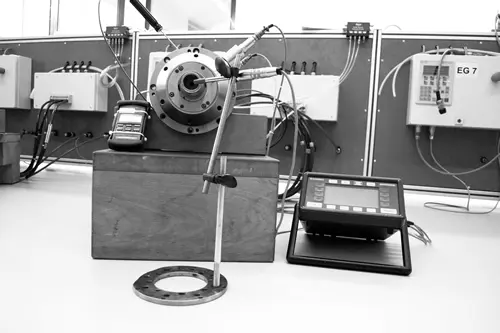

A complete IBAG spindle system includes the high speed spindle motor, bearing lubrication components, electronic spindle motor drive package, and spindle cooling unit. The support systems are engineered and built in the USA, to provide long, dependable service. Custom systems are also possible, with special mechanical bracketry, electrical interfacing, and system monitoring to integrate with your CNC.

High Speed Spindle Applications for OEMs

High frequency CNC milling spindles provide profound application features that cannot be matched by other processes. By working closely with machine tool OEMs, distributors and end users, we have worked on hundreds of high speed cutting applications, including spindle selection, feeds & speeds, ROI, and workholding requirements. Our high speed spindle applications include:- Die Cutting

- Soft Materials

- Mold & Die

- Micro Drilling

Installation & Engineering Services for High Speed Spindles

To successfully introduce a high speed spindle into an existing manufacturing process, it is necessary to have extensive knowledge and experience in proper machine integration. For over twenty five years, IBAG North America has successfully sold, installed, engineered, and serviced high speed CNC spindles. Each application requires the right spindle, carefully matched to the part requirements and specifications.High Speed Spindle Repairs, Parts and Accessories

IBAG North America provides repair, installation and rebuilding services for all IBAG high speed spindles. All repair work, including bearing replacements, balancing, run-in, and vibration testing is performed in our modern North Haven, Connecticut facility.High Speed Spindle Options

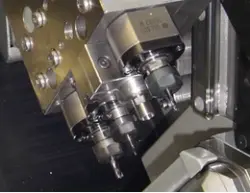

IBAG high speed spindles use the most advanced bearing technology available today, including hybrid ceramic, angular contact ball bearings with advanced micro oil-air bearing lubrication systems. We offer the following high speed milling spindle options:Micro Spindles

Small Spindles

Medium Spindles

Large Spindles

Plug-N-Go Spindles

Special Spindles

CNC Machine Integration

High Speed Spindle Tooling

Depending upon the application and accuracy requirements to provide complete mill, drill, and grinding services, various tool holding systems must be utilized. IBAG offers a wide range of additional tooling and accessories for your spindle systems. Learn about our services to help your manufacturing process run smoothly and efficiently.View IBAG's 2015 Motor Spindle Catalog

High Speed CNC Spindle Retrofit Systems

At IBAG North America, we deliver custom machine retrofit systems, including small and large spindles, as well as multi-spindle applications. All design work is done in AutoCAD and Solidworks, providing reliable digital documentation. Custom bracketry, tool changer component parts, spindle drives, and custom electrical PLC systems that are designed and fabricated in our own workshop.

.jpg1458312500250166.5600250166.5.thumb.webp)

.jpg1458312500250166600250166.thumb.webp)